ALLOY WHEEL R&D

ALLOY WHEEL R&D

-

R&D Center >>

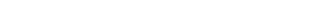

We continuously develop through innovative technology and quality managementHyundai Sungwoo Casting produces high-quality, high-performance alloy wheels with the world’s best design capabilities, unique manufacturing methods, and strict quality assurance. Hyundai Sungwoo Casting will continue to develop innovative technologies that brings convenience and safety to the lives of customers, and ultimately lead to a prosperous future.

-

-

From development stage, we conduct rigorous tests that exceed international quality standards to secure reliability and quality of products. Ranging from compact passenger cars to high-end large vehicles, we heavily invest for future technologies to improve weight lightness, strength, fuel efficiency, braking power, and safety.

-

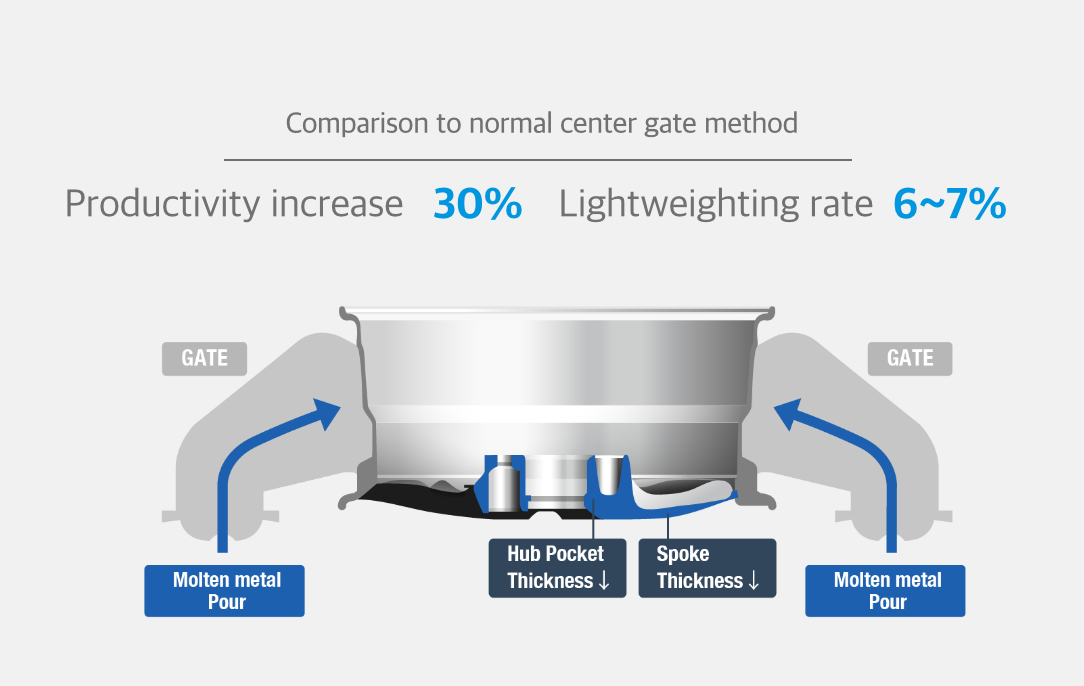

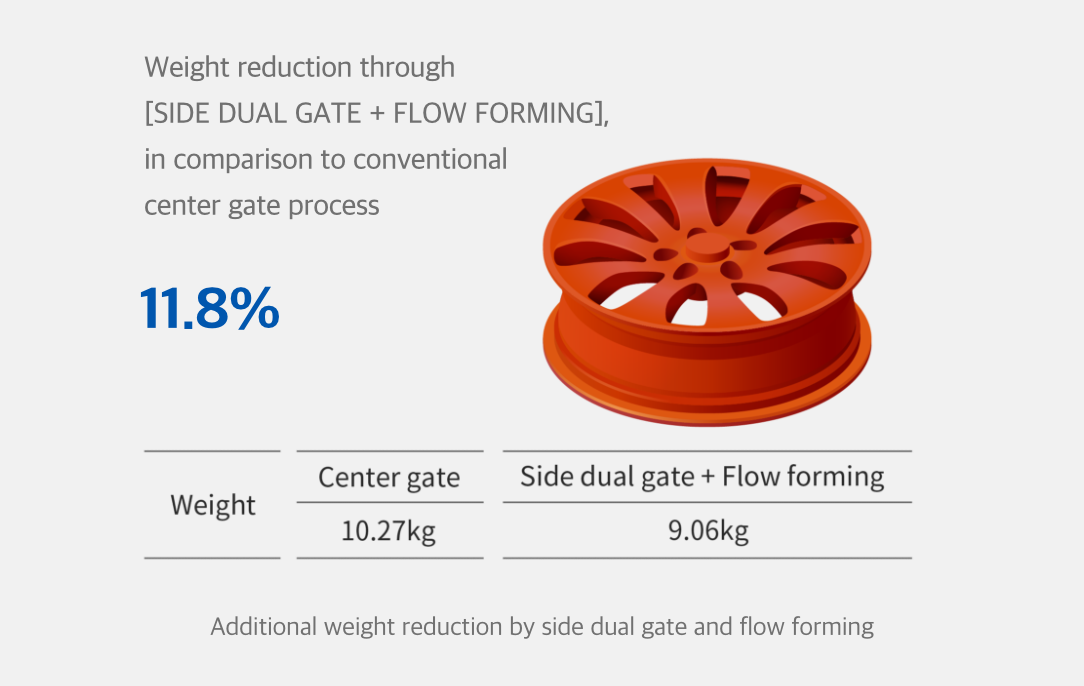

Side Dual Gate

A method of pouring molten through gates on the side of a rim. Compared to center gate, side dual gate method allows weight reduction by improving mechanical properties and productivity.

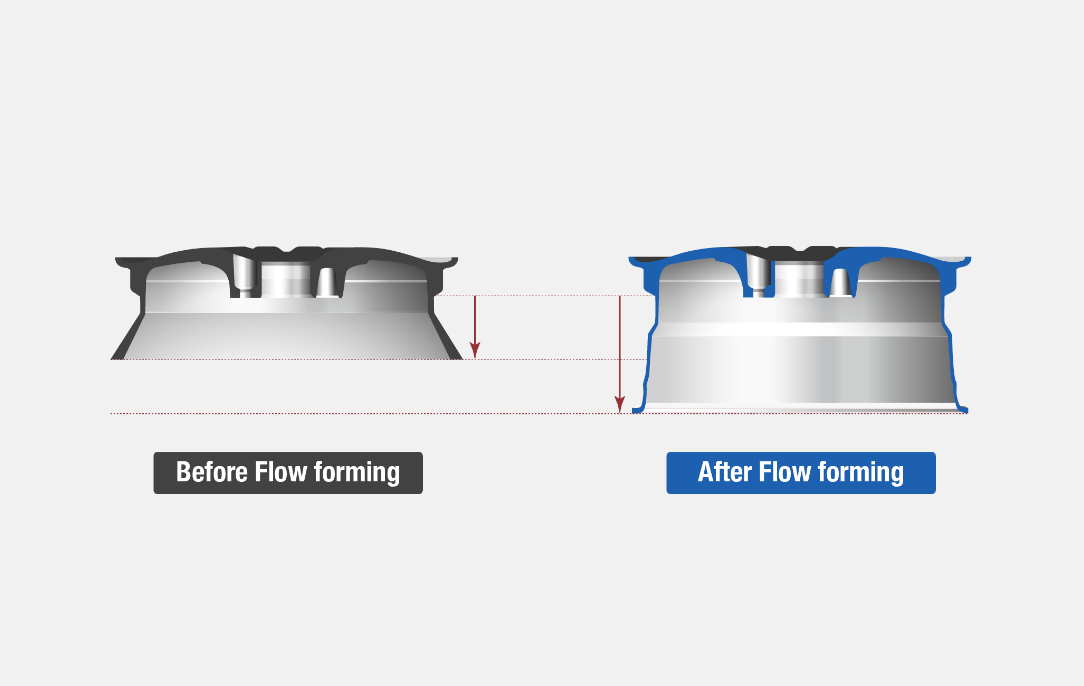

Flow Forming

Technology of enabling weight reduction by 5% through fine micro structure of the rim. Also responsible for safe driving, it is applied to various vehicles including Hyundai Genesis Line, Kia Sorento and K5 models.

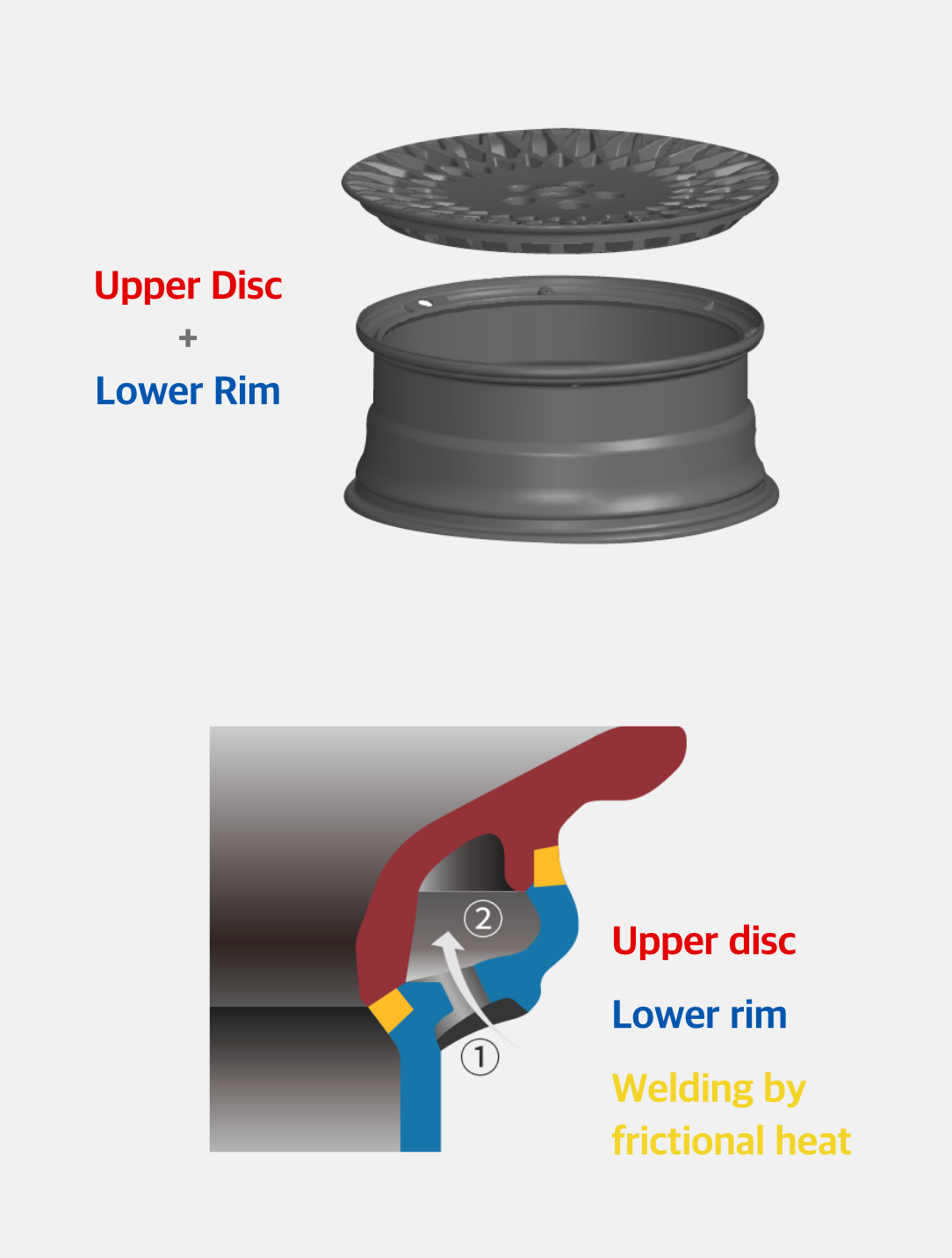

FSW(Friction Stir Welding)

A technique used to build Helmholtz Resonator in a wheel by joining the disc and rim using heat generated by friction between a non-consumable rotating tool and workpiece (disk and rim). With a hollow chamber inside the wheel, not only is weight reduced but NVH (Noise, Vibration, Harshness) is improved for a smooth and silent ride.